Some Known Incorrect Statements About Plastic Injection Molding

Wiki Article

Top Guidelines Of Plastic Injection Molding

Table of ContentsPlastic Injection Molding for DummiesThe Best Guide To Plastic Injection MoldingFacts About Plastic Injection Molding UncoveredThe smart Trick of Plastic Injection Molding That Nobody is Discussing

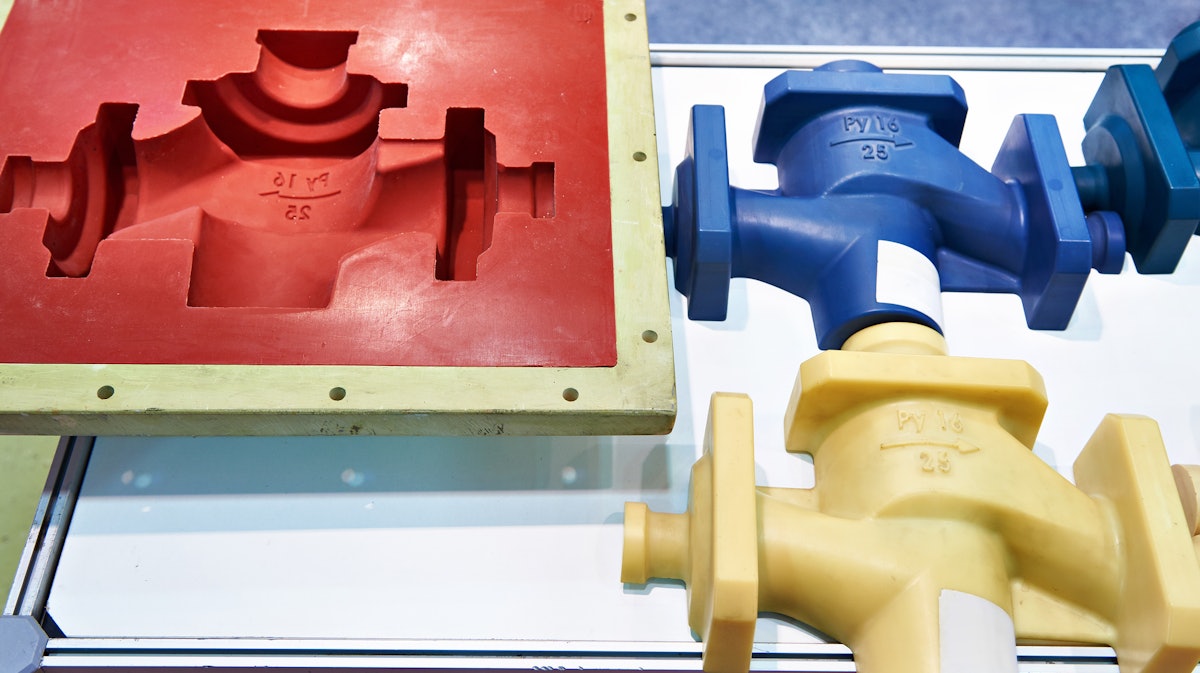

If you intend to discover further, the overview covers sorts of mould tools, in addition to special completing processes such as colours & plating. Words that are underscored can be located in the reference in the appendix ... Part I: Moulding: The Fundamentals The Advantages of Shot Moulding Plastic shot moulding is an extremely precise procedure that provides numerous advantages over various other plastic processing techniques.

Precision is best for extremely intricate parts. You can hold this moulding in the hand of your hand and it has managers, ribs, steel inserts, side cores and also holes, made with a moving closed off attribute in the mould tool.

The molten plastic cools down & sets into the shape inside the mould tool, which then open up to permit the mouldings to be expelled or eliminated for inspection, shipment or additional procedures. Phase 1Material granules from the hopper feed into the heated barrel & turning screw. Product thawed by warmth, rubbing & shear pressure is compelled through a check valve to the front by the rotating screw ... Part III - Beyond the Fundamentals - Tooling Options Manufacturing in China can conserve you a whole lot of price, yet it can come with problems such as delivery delays, miscommunications, inferior quality and the paperwork surrounding importation. Using a UK moulder with existing connections to China can remove the risk and still result in cost-saving ... Cavity - The part of an injection mould device that gives the plastic product its shape, that does the real moulding of the plastic. Also see mould device phase on pages 5 and also 6 for all terms connected with the mould device Cycle time - The time it takes for a mould cycle to be completed, i.

Plastic Injection Molding - The Facts

from product feed & melting; product shot; cooling down time and ejection to the re-closing of the mould tool all set for the next cycle. Draft angles - The walls of a moulded part must be somewhat tapered in the direction in which the part is ejected from the mould device, to enable the part to be expelled quickly.Ejector stroke - The pushing out of ejector pins to eject the moulded component from the mould tool. Ejector stroke speed, size and timing requires to be carefully managed to stop damages to the ejectors as well as mould tool, but at the very same time make the moulding cycle as brief as feasible.

Plastic Injection Molding Can Be Fun For Everyone

Overlocking - When a mould tool has actually been established into a moulding device inaccurately, triggering the device to close too difficult therefore damaging the mould tool Part repeatability - The capacity to produce the same plastic part-times after time Radii - Flawlessly straight edges are difficult to expel from the mould device.Ribs - When a plastic part has slim walls, ribs are included in the layout to make the thin walls stronger Side cores - Side activity which generates a feature on a moulded component, at an opposing angle to the normal opening direction of the mould tool. The side core requires to be able to withdraw as the plastic component can not be ejected otherwise.

Walls - The sides of a moulded part The text on this web page is a sample from our full White Paper 'Shot Moulding for Purchasers'.

Manufacturing process for generating parts by infusing liquified product right into a mould, or mold and mildew Simplified layout of the procedure Injection moulding (united state punctuation: injection molding) is a production procedure for producing components by infusing liquified product into a mould, or mold and mildew. Shot moulding can be performed with a host of materials mainly including steels (for which the process is called die-casting), glasses, elastomers, confections, and a lot of more tips here frequently polycarbonate and my site also thermosetting polymers. Injection moulding is extensively utilized for manufacturing a range of components, from the smallest parts to whole body panels of autos. Breakthroughs in 3D printing technology, utilizing photopolymers that do not thaw throughout the injection moulding of some lower-temperature thermoplastics, can be utilized for some basic shot moulds. Injection moulding utilizes a special-purpose maker that has three parts: the shot system, the mould and also the clamp.

The Best Guide To Plastic Injection Molding

In several cavity moulds, each dental caries can be similar and form the same components or can be distinct and form numerous various geometries during a single cycle. Moulds are generally made from device steels, yet stainless steels and aluminium moulds are appropriate for sure applications. Aluminium moulds are normally ill-suited for high quantity manufacturing or get that site rid of narrow dimensional tolerances, as they have inferior mechanical homes as well as are more susceptible to put on, damages, as well as deformation throughout the shot and clamping cycles; however, aluminium moulds are cost-effective in low-volume applications, as mould construction prices as well as time are considerably reduced.

The screw provides the raw product ahead, mixes and homogenises the thermal and also thick circulations of the polymer, and reduces the required home heating time by mechanically shearing the product and also adding a significant amount of frictional home heating to the polymer. The product feeds forward through a check valve and also gathers at the front of the screw into a quantity called a shot. When sufficient product has gathered, the material is forced at high stress as well as velocity right into the component creating cavity. The exact amount of shrinkage is a feature of the material being utilized, as well as can be relatively predictable. To stop spikes in pressure, the process generally utilizes a transfer position corresponding to a 9598% complete dental caries where the screw changes from a continuous speed to a constant stress control.

The packaging pressure is applied until the gateway (dental caries entry) solidifies. Due to its tiny size, the gate is usually the first area to solidify through its entire thickness.: 16 Once the entrance solidifies, no even more material can enter the dental caries; as necessary, the screw reciprocates and obtains product for the following cycle while the material within the mould cools so that it can be expelled and be dimensionally steady.

Report this wiki page